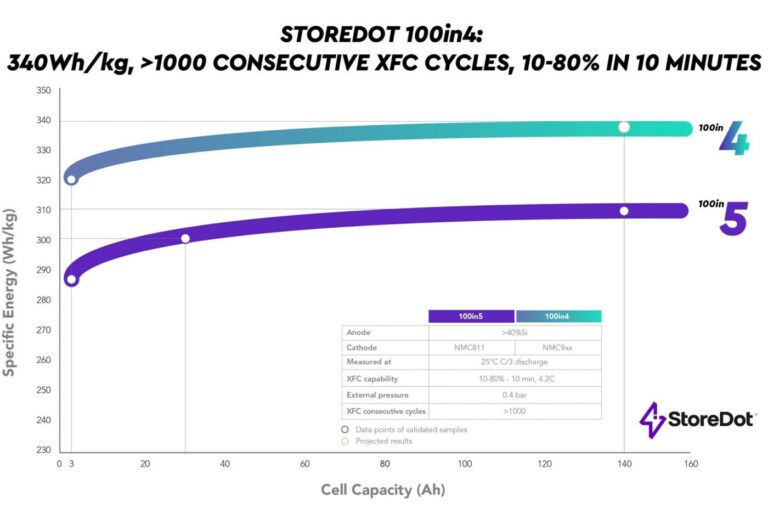

According to the company, it achieved the target of 1,100 cycles with a prototype cell earlier than planned. The cell will also have a predicted energy density of 340 Wh/kg “in a large Electric Vehicle form factor.” The cell chemistry at the cathode is specified as “NMC9xx,” while the company’s silicon-based technology is used at the anode

As is often the case with such reports on battery developments, it is a laboratory test with a small-format prototype cell. The results cannot be transferred 1:1 to ready-to-install battery cells in vehicles. In the case of the current StoreDot demonstrator, it is a cell with a capacity of 3 Ah, which is hardly suitable for automotive use. The “100in4” technology will be scaled to a 140 Ah cell. The tests with this cell should then be much more conclusive.

“While this is an early prototype and there are still challenges to overcome, we can draw from our experience of seamlessly scaling up from a 3Ah to a >100Ah EV grade cell within months,” says StoreDot CEO Doron Myersdorf. “We believe our roadmap provides a sustainable, practical, and proven path to delivering extreme fast charging that will accelerate mass EV adoption. We remain ahead of schedule for our planned milestones as we continue our path to commercialization.”

StoreDot presented its strategic technology roadmap “100inX” in March 2022. The first stage, “100in5,” is planned for 2024 and will be able to recharge electricity for those 100 miles or 160 kilometres in five minutes. At that time, the “100in3” technology (i.e. recharging 160 kilometres in 3 minutes) was announced for 2028, which will be solid-state cells with an energy density of around 450 Wh/kg. “100in4” for 2026 would thus be the logical intermediate step.

In October 2022, the Israelis demonstrated that StoreDot can achieve high cycle numbers with cells in a production-ready format. At that time, a large-volume pouch cell with “100in5” technology was subjected to 1,200 cycles. Even after that, the 30 Ah cell still had over 80 per cent of its original capacity.

Until now, StoreDot has primarily focussed on pouch cells. However, at the end of January 2024, the company announced that it would also transfer its battery technology to prismatic cells. Unlike soft pouch cells, prismatic cells have a fixed housing and can thus be structurally loaded in the battery pack – as is the case with many cell-to-pack concepts. Pouch cells, on the other hand, are first packaged in modules and then integrated into the battery pack – which leads to a lower energy density at pack level with identical energy density at cell level.