Regarding high-performance engine programs, Lingenfelter Performance Engineering (LPE) has decades of knowledge, development, and expertise that were combined in the creation of their Eliminator LS engines several years ago. With improvements in engine components, processes, and knowledge, LPE is excited to announce a few updates and additions to its Eliminator Spec engine and performance parts program.

The Eliminator Spec engine program epitomizes the idea of an engine with track-ready performance and street versatility. According to Lingenfelter COO/VP Operations, Mark Rapson, the goal of the Eliminator Spec program is to offer complete engine packages to customers that have been tested and proven to meet the demands of severe track duty while remaining docile and drivable enough for a street car. That’s a fine line to walk, but Rapson is positive the various engine packages offered in the Eliminator Spec program achieve that goal.

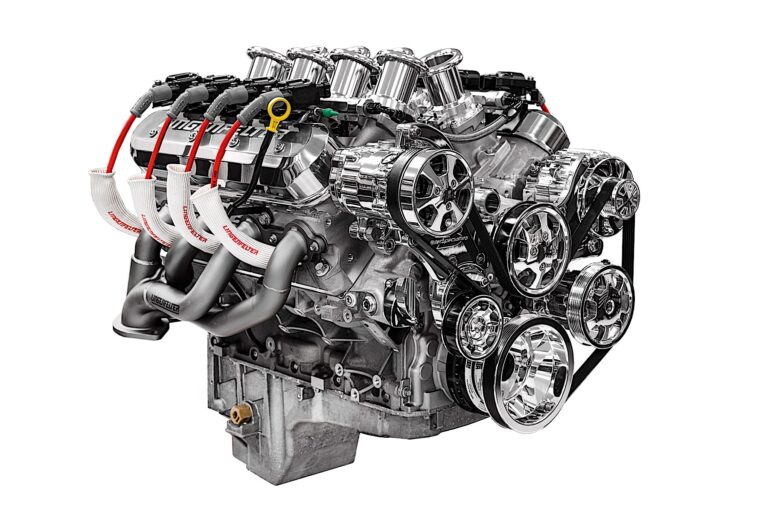

Gone are the conventional approaches to crate engines, as Lingenfelter aims to raise the bar for what an engine is capable of on the track and the street. The Eliminator Spec packages cater to late-model GM vehicles featuring Gen-IV (LS) or Gen-V (LT) engines. Central to this program are the Lingenfelter blueprinted and CNC machined blocks. As each Eliminator Spec engine moves through the build process, every internal component installed adheres to Lingenfelter’s exacting specifications, incorporating forged rotating assemblies, CNC-ported cylinder heads, custom-ground camshafts, competition-grade fasteners, precision balancing and blueprinting procedures, among other proprietary processes and components.

Lingenfelter Performance Engineering has built its legacy on producing reliable high-performance engines and components that win races, qualities that define its Eliminator Spec engine packages. To meet the many requests of its customers, LPE offers Eliminator Spec engines that span various performance tiers, each distinguished by a designated letter classification.

Sitting atop the peak of the Eliminator Spec engine program is the X-Spec engine. It is engineered for experimental, developmental, and extreme performance applications. The X-Spec package is for customers who work with the team at LPE on aspirational products to showcase what is possible from Lingenfelter Performance Engineering. Think of this as the “skunkworks” part of the program where LPE gets to run wild with ideas to test and use for developing new parts and packages to offer customers.

Professional drift car competitor Dirk Stratton uses an Eliminator R-Spec LS engine in his C6 Corvette for its performance and reliability during the sustained high-rpm laps seen in drifting events.

For professional racing programs wanting the ultimate in performance from their engine programs LPE offers the R-Spec engine package. The R-Spec features engine combinations with high compression, running on race fuel, and components designed for competition applications. These engine builds include performance products backed by years of testing and race-winning applications. The R-Spec exceeds the demands of road racing, autocross, drag racing, and other motorsports.

The third package being offered in the Eliminator Spec engine program is the S-Spec. This engine series is engineered for high-performance street driving applications while being competition-capable on pump fuel. The S-spec is recommended for customers wanting increased performance, drivability, and reliability. These engines are built using validated performance products derived from the Eliminator X- and R-Spec programs.

Eliminator S-Spec engines can be found in every CF-1 Roadster built by Kindig It Designs.

Additionally, Lingenfelter announced that it will launch several new performance products for 2024 that are used in the Eliminator Spec engine program. Commanding the valvetrain in the engines will be a new series of Eliminator camshafts for LS, LT1, and LT2 applications. LPE took its race-winning cam designs and updated them with new lobe ramp and lift profiles for greater horsepower and better torque curves with improved valvetrain performance. The new Eliminator Spec camshafts have been tested in LPE race-winning engines over the past year.

To work in harmony with the new camshafts, LPE has developed new CNC cylinder heads that feature improved port designs and valve profiles to optimize performance with the line of Eliminator camshafts. To add to the new Eliminator cylinder heads LPE also has new high-performance conical valve springs. According to Lingenfelter, the decision to develop new springs for the new heads was to offer better high-RPM valve control, reduce wear, and maximize efficiency and performance

While Lingenfelter’s new Eliminator Spec engine program is big news, even more exciting is LPE’s use of Formula One technology in the Eliminator Spec performance parts program. Born from F1 R&D, LPE has new carbon fiber pushrods that will be put to work in the Eliminator engine program. These carbon fiber pushrods push the envelope of valvetrain technology and performance. Weighing in at less than half of what a typical high-performance pushrod weighs, the Eliminator carbon fiber pushrods allow for lighter spring seat pressures and reduced harmonics in the valvetrain at high rpm. Incorporating a component like this into high-performance American V8s is something we love to see. We will be taking a deep dive into the technology and performance of the LPE Eliminator carbon fiber pushrods in an upcoming story.

Lingenfelter Performance Engineering has rolled into 2024 with a focus on pushing the limits of what is possible with complete engine packages that are “Engineered for the track, bred for the street.” We look forward to seeing Eliminator engines in show cars, street cars, and race cars. For more information on the Eliminator Spec engine and performance parts program head over to the Lingenfelter Performance Engineering site.