It was planned very differently. Following the initial plans, we would have published detailed driving reports on the Porsche Macan and other PPE electric vehicles by now. If the original schedule had been adhered to, then the Macan and Audi models such as the Q6 e-tron and the classic A6 e-tron company car would already be on the market or shortly before their premiere. With the various delays, there is still no final production model at the end of 2023. It is only becoming apparent that Porsche will be ahead of the Q6 e-tron with the world premiere of the Macan following the further delay at Audi. It is not yet publicly known which of the two SUVs will actually be delivered to customers first.

In the run-up to the world premiere, the Zuffenhausen-based company organised a technology workshop in Leipzig, where the upcoming electric Macan will be built alongside the existing combustion engine model. The engineers gave a preview of the technology of their first PPE model – and thus also of the platform itself. This much in advance: Porsche has endeavoured to talk primarily about the Macan and to tease the new model – and not so much to emphasise the differences to Audi models.

The drive

Let’s start directly with the drive: Porsche relies without exception on permanently excited synchronous electric motors (PSM), and no asynchronous machine or current-excited synchronous machine is used on the front axle either. The advantages and disadvantages were carefully weighed up, as drive developer Antoon Janssen explains. Although the permanent magnets in the rotor result in higher costs, the advantages of high energy density (enabling a more compact design), high efficiency (for high continuous performance) and good thermal behaviour (consistent performance and service life) ultimately outweighed the disadvantages for Porsche.

The Taycan also relied on the PSM principle, with features such as the hairpin windings in the stator making their debut back then. These hairpin-shaped copper rods instead of coils made of wound copper wire increase the copper filling level in the stator – and therefore the energy density. However, numerous points have been improved for the Macan-PSM. The so-called double V-cut arrangement of the magnets within the rotors has been optimised, as has the water jacket cooling for maximum power density.

As a result, Porsche’s first PPE model has three drive units for the initial two variants. The basic model uses a motor with a diameter of 210 millimetres and an “active length” of 100 millimetres on the front axle – the housing itself is longer than these ten centimetres. An engine with a diameter of 210 millimetres is also used on the rear axle, but the active length is 200 millimetres. The more powerful Macan variant uses the same front drive, but a more powerful unit is installed on the rear axle. This PSM has a diameter of 230 millimetres and an active length of 210 millimetres.

Porsche does not intend to publish the final output and model designation until the world premiere. Until then, it remains with the already known information that the system output will be “around 450 kW” and the maximum torque will be “over 1,000 Nm”. Of course, this applies to the top model, which with its 612 hp probably deserves the name suffix ‘Turbo’, which is also used by Porsche in the electric world. As the engines in the entry-level model do not differ too much from the top model, this variant could make its debut as the Macan 4S according to Porsche logic.

Regardless of which PSM is installed, the power flow to the wheels is realised at the front and rear axle via a two-stage input gearbox. Instead of a large gearwheel, the transmission is realised there with two smaller gears, hence the two-stage design. This enables “a particularly compact design”. However, there is a difference in the rear engine of the top model: here, the engine is installed in the so-called “performance rear carriage” – not on, but behind the axle. This positioning not only ensures a better weight distribution of 48:52, but also creates space for the actively controlled transverse lock in the differential – more on this in the chassis section.

While the Taycan still had the option of using only the front PSM in the so-called ‘Range’ mode in certain speed ranges for reasons of efficiency (and was therefore a Porsche with front-wheel drive), this is no longer provided for in the Macan – the complete “Range” mode has been cancelled. Although Porsche claims that the drive torque can be distributed fully variably between the front and rear axles, the rear electric motor is now favoured at low loads. The simple background: the inverter (or pulse inverter, as Porsche calls it) on the rear axle works with silicon carbide semiconductors and is therefore significantly more efficient. Silicon is still used on the front axle. In other words: in moderate driving conditions, the electric Macan is rear-wheel drive. In this case, the front axle runs passively and can provide drive torque again immediately if required.

The front PSM is probably used less in everyday driving, but mainly for recuperation. Up to around 240 kW can be recovered in the Macan, depending on how hard the driver presses the brake pedal and depending on the temperature and state of charge of the battery (SoC), among other factors. This corresponds to a deceleration of around 4.3 m/s. Incidentally, the engineers have dispensed with one-pedal driving for the driving behaviour typical of a Porsche – depending on the driver’s wishes, the Macan sails or the so-called “thrust recuperation” decelerates at around 0.6 m/s when the driver releases the accelerator pedal – which roughly corresponds to the deceleration of the engine brake in a combustion engine. Only when the driver steps on the brake pedal is there more recuperation. If greater deceleration is required, the hydraulic disc brake is applied imperceptibly for the driver.

Incidentally, the PPE is not tied to Porsche’s PSM. The Zuffenhausen-based company builds the electric motors for the Macan in Stuttgart, while Audi manufactures its electric motors at its own engine plant in Györ, Hungary. The platform is therefore flexible enough to accommodate different motors – also an interesting feature with a view to the future.

The battery

Although there are two drive variants, there are no battery variants (for the time being). All Macan models come with a lithium-ion battery installed in the underbody with a gross capacity of around 100 kWh – the exact value will not be available until the world premiere. The battery system will be assembled by Dräxlmaier on behalf of Porsche (as in the Taycan); the supplier has built its own plant in Leipzig for this purpose. There, 15 prismatic NCM811 cells are installed in each module and twelve modules are then integrated into the housing – with a cooling plate and an underride guard made of glass fibre composite material to protect the battery from mechanical damage from below. The total weight of the battery is 570 kilogrammes.

Porsche obtains the cells themselves from CATL – not from China, however, but from the Chinese company’s first European plant near Erfurt. The cells use nickel, manganese and cobalt at the cathode in a ratio of 8:1:1, which not only means around 60 per cent less cobalt, but also around 30 per cent higher energy density according to Porsche. The battery’s repairability has probably also been improved. Even when explicitly asked, the Porsche developers were unwilling to make a statement about the anode. In the Taycan, a certain amount of silicon was added to the graphite. Whether this is also the case in the Macan or whether the silicon was omitted for cost reasons is therefore not confirmed.

The “foot garages” familiar from the Taycan (battery modules have been omitted in front of the rear seat bench to allow a more comfortable kneeling angle for the passengers) do not exist in the Macan, however, there is a different seating position in the SUV anyway. Although the modules are installed flat in the battery housing, the battery is not completely flat: at the rear end under the rear seat bench, the battery management system is installed on the battery cover. The system, which Porsche calls BMCe, not only monitors the cell voltages and the entire current flow in the high-voltage system, but also distributes the electrical power to the electric motors and the high-voltage auxiliary consumers and enables DC charging at 800 and 400 volts. The safety systems for the battery, such as fuses and a pyrotechnic isolating element, are also located there. In the event of overvoltage, short circuits or an accident, the HV battery can be electrically disconnected from the rest of the vehicle in a fraction of a second.

Another new feature is that the battery protects itself against excessive temperatures when the vehicle is parked. If the vehicle is parked with a high charge level in a hot environment and the cells heat up to between 35 and 45 degrees due to the sunlight and remain there for many hours, the battery conditioning is activated. The cells are then not only actively cooled, but the energy consumption also reduces the charge level – which further reduces the stress on the cells. If the charge level is below 50 per cent, the stress on the cells remains within reasonable limits even at high temperatures, so that the conditioning is not activated – meaning you still have enough power to get to the next charging station.

The charging system

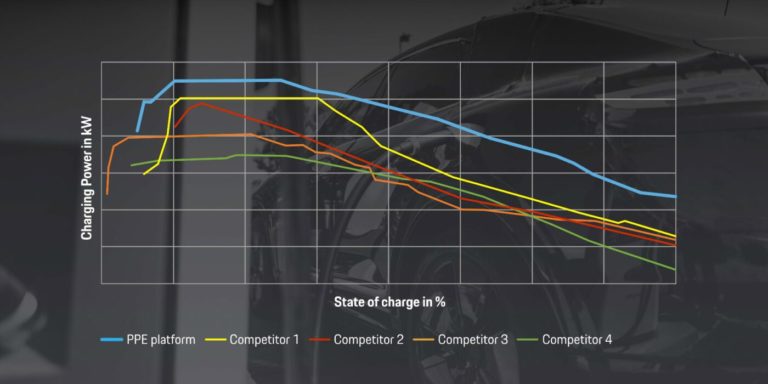

When it comes to the battery, let’s stick with DC charging: This is possible in the Macan with up to 270 kW, and the battery can be charged from 10 to 80 per cent in less than 22 minutes. Compared to the four-year-old Taycan, this doesn’t sound like much of an improvement at first – Porsche had specified 22.5 minutes from five to 80 per cent. However, the battery in the Macan is also slightly larger.

It would be interesting to know whether or not silicon is still used at the anode in the Macan. If Porsche has achieved the 270 kW with a presumably flatter charging curve without silicon, that would be an improvement not to be sneezed at – especially in terms of costs. After all, significantly more vehicles are likely to be built of Porsche’s best-selling Macan than of the electric pioneer Taycan.

It is already known that the Macan battery supports “bank charging”. This involves splitting the battery into two blocks using high-voltage switches if the charging station only offers 400 volts. The two 400-volt batteries instead of one 800-volt battery can be charged in parallel with up to 150 kW.

All of this is controlled in the BCMe unit located under the rear seats. Due to this installation position, Porsche and Audi have decided to position the charging ports above the rear axle again – and no longer between the front door and front axle as in their first Taycan and e-tron quattro models. The DC connection is located on the left-hand side of the vehicle, with a pure AC connection on the right. Thanks to a new control unit (Smart Actuator Charger Interface Device, SACID), Plug&Charge is possible at both charging sockets.

In addition to the BCMe, the so-called Integrated Power Box (IPB) is also installed, which combines the AC onboard charger, the high-voltage heater and the DC/DC converter in one housing. This patent-pending solution is not only more compact, but at 19 kilograms it is also three kilograms lighter than conventional components. As the onboard charger is no longer located under the front hood, the frunk could also be made larger. According to Porsche, the onboard charger will have an output of eleven kW “at the market launch of the Macan” – a formulation that leaves room for improvement.

The IPB’s high-voltage heater has an output of six kilowatts and is used to heat the battery. This allows the battery to be preconditioned so that the cells are always in the optimum temperature range for driving and fast charging – between 20 and 25 degrees. Above 30 degrees and below 20 degrees, the charging time increases noticeably.

The system is activated as usual via the Porsche Charging Planner, the charging route planning in the integrated navigation system. Here the search filters have been refined so that customers can not only search for (or specifically exclude) charging operators for route planning, but also according to charging capacity.

The software

The Charging Planner is the transition to the software. At first glance, the controls on the touchscreen (or the touchscreens with the optional passenger display) look familiar, but the technology in the background is completely different. The new PCM generation uses Android Automotive OS as its operating system. Important: This is the operating system and the software ecosystem, but not Google services. Porsche has programmed its own solution with this operating system in order to maintain its own user interface and menu navigation.

For the navigation system with the charging route planner, this means that the user experience should be significantly improved thanks to monthly map updates and online-based charging route calculation. The navigation app can plan the route with charging stops “in a matter of seconds” – according to Porsche, “regardless of whether it’s to Berlin or Barcelona”. The respective customer preferences for charging station types and providers will also be taken into account. We are already looking forward to the first tests of the final software version in the vehicle – because if the vehicle is stuck in a dead zone or a planned charging station is offline after all, an expensive Porsche should still have an answer for its users.

Another advantage of the switch to Android Auto: Porsche now has its own App Centre, which customers can use to install apps from third-party providers – the range is set to increase steadily. The music services Spotify, Amazon Music and TuneIn Radio, the streaming platforms YouTube and DAZN, the conference system ‘Cisco WebEx’ and the smart home app ‘Home Assistant’ are available on the European markets at the start. In other words, you will be able to use your Spotify playlists in the Porsche environment in future and will not have to use Apple CarPlay or Android Auto. Speaking of CarPlay and Android Auto: if you use one of these systems for navigation, the map from Apple or Google Maps can also be displayed in the instrument cluster in future – previously this was only possible with Porsche’s own navigation system.

The new operating system has also made it possible to implement a better voice assistant. This should not only respond faster but also understand six additional languages, making for 23 in total. Thanks to two microphones, the assistant can also determine whether the driver or front passenger has said “Hey Porsche” to activate the system – the system shows who it is listening to in the central display and via a “communication light”.

This is standard ambient lighting in the front area, consisting of 56 LEDs. This colourful and animated light strip visualizes various vehicle statuses, such as the charging process, and greets passengers with a show when they get in. Launch Control or the change of driving modes can also be highlighted here, and assistance systems also have access to it – the lane change assistant can warn of a vehicle or bicycle in the blind spot, for example.

For the first time at Porsche, a head-up display with augmented reality technology is also available as an optional extra. The image of the head-up display appears at a distance of ten meters and corresponds to the size of an 87-inch display. According to Porsche, this head-up display is “one of the largest currently offered by the competition”. The special displays, which also use the vehicle’s environmental data and position, are designed to make it quicker and easier for the driver to grasp instructions and information.

The chassis

Back to the hardware for a moment, but a part that is not directly related to electromobility. Porsche has also introduced some changes to the chassis for its PPE debut, and not just with the “performance rear end” of the top model. Basically, the suspension has been designed to offer a wider range between everyday comfort and sports car behaviour.

The suspension uses steel springs ex works, but can also be upgraded with the electronic damper control system PASM (Porsche Active Suspension Management). The optional air suspension is always equipped with PASM. New in PASM are dampers with two-valve technology. Thanks to a larger damper map, the spread between comfort and performance is more pronounced, and the rebound and compression stages can be controlled separately. Compared to single-valve technology, the force potential in the compression range is significantly greater – this ensures excellent pitch and roll support as well as less movement in the vehicle.

The new packaging on the rear axle also makes it possible to install rear-axle steering for the first time. When manoeuvring, the rear wheels turn up to five degrees in opposite directions, which makes the Macan easier to handle – the turning circle is then 11.1 meters. The Macan also steers more dynamically into bends. At speeds above around 80 kph, the rear wheels turn in the same direction as the front axle. The result: a virtual wheelbase extension and thus even greater driving stability. The rear axle steering is also accompanied by a 15 per cent more direct steering ratio on the front axle.

How does that feel? Rapid. Porsche did offer cab rides on the factory’s own test track and the off-road course as part of the technology workshop – however, the development engineers behind the wheel were driving on a circuit at a level that had little to do with normal road traffic. The Macan’s off-road capabilities on uphill and downhill gradients are also rarely required in practice. However, on the bumpy stretches of the off-road course, it was noticeable that the air suspension of the pre-production car absorbed all the bumps surprisingly well.

The factory

The electric Macan, like the first generation (which will remain in the range for a while), is built in Leipzig. The company has invested around 600 million euros in what is now the fifth expansion of the site, which produced the first Cayennes in 2002. Full production has only been carried out in Leipzig since 2013 with the first Macan; the bodies for the Cayenne and the first Panamera generation (since 2009) were still supplied.

Final assembly of the old and new Macan and the second-generation Panamera takes place on one line – up to 550 vehicles a day. The processes only differ at the start of the line: Where the combustion engines make a small extra loop to assemble the drives and exhaust systems, a robot takes over the assembly of the heavy battery in the electric Macan. However, the remaining steps through the assembly hall are the same.

Incidentally, the sixth expansion stage in Leipzig for the electric future is already under construction: excavators and construction machinery are already rolling on the former green area south of the existing plant. This is where the assembly line for the electric model, known internally as the J1, is being built.

Source: Info via email