Bosch is aiming to buy back and recycle its fuel cell stacks at the end of their service life. The technology group is primarily targeting the recovery of so-called platinum group metals (PGMs) that are processed in fuel cells.

According to Bosch, at least 95 per cent of platinum, for example, can be recovered from the stacks and used in new stacks. Platinum acts as a catalyst in the fuel cell, accelerating the reaction of hydrogen and oxygen. “By recycling, we can make the stacks more economical and at the same time reduce the carbon emissions associated with platinum mining,” says Thomas Pauer, the president of the Bosch Powertrain Solutions division. “We’re already laying the groundwork for recovering rare raw materials like platinum. Our estimates suggest that by 2030 at the latest, appreciable numbers of fuel cells will need recycling,” he adds.

A first step in Bosch’s recycling plan is a contract with mobility provider Hylane that governs the possible buyback of fuel cell stacks by Bosch at the end of their service life. The Cologne-based startup rents out hydrogen trucks equipped with Bosch fuel cell drive systems, among other things — specifically, the Iveco Heavy Duty FCEV (previously Nikola Tre FCEV). The new contract model with Hylane assures Bosch a buy-back option of the stacks for mobile applications. They are to be recycled at a third-party supplier. Bosch intends to use the recovered platinum in the following year.

In the long term, the contract model could serve as a blueprint for further Bosch fuel cell activities in the mobile and decentralized sectors, as well as for electrolysis stacks. “In this way, we can create predictable and stable supply chains and improve the availability of resources. Using recycled platinum lets us greatly reduce stacks’ absolute carbon footprint since we avoid the emissions that would otherwise occur during the mining of the metal,” says Thomas Wintrich, head of the mobile fuel-cell business unit at Bosch.

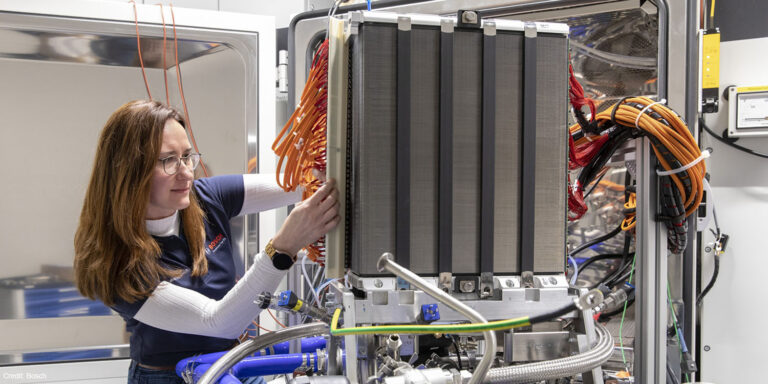

Bosch began the series production of its fuel cell drive system at its Stuttgart-Feuerbach site in July. The pilot customer is US company Nikola with its H2 truck, scheduled to hit the North American market in the third quarter of 2023. Although the final assembly of the entire fuel cell system takes place in Stuttgart-Feuerbach, the stack is supplied by the Bosch plant in Bamberg and system components such as the electric air compressor or the recirculation blower are supplied by the Homburg plant. Bosch did not say in July how many units would now be produced.

Parallel to Feuerbach, production of the fuel cell drive system is also starting in Chongqing, China, with the necessary components coming from the plant in Wuxi. Bosch is also planning to manufacture stacks for mobile applications at its US plant in Anderson, South Carolina.