At Power Automedia, we have many projects going on at once, just like some of our readers. Sometimes, we might have an issue with a build and need some expert advice to help guide us in the right direction. We needed a fuel system for our street/strip 2000 Chevy Silverado that will be powered by a boosted LS engine capable of making north of 1,000 horsepower. Who better to ask than the experts at FueLab who make the parts that can solve our problem?

FueLab introduced brushless fuel pump technology to the market over ten years ago. They are constantly pushing forward, manufacturing the most innovative fuel systems. FueLab’s high-flow fuel pumps are efficient and designed to handle multiple fuels and pressures while holding up to the harshest conditions.

FueLab offers all of the components needed to build a fuel system. All you need is a fuel cell or factory tank to complete the fuel system.

We will walk you through the complete installation, from mounting the fuel pump and tank to installing the regulator. FueLab has a very informative website where a fuel pump calculator can be utilized to estimate fuel delivery needs based on desired horsepower, fuel pressure, and fuel type. It’s easy: select your fuel type, key in your desired horsepower and fuel pressure, and select if your engine is a naturally aspirated, nitrous, or forced induction application. Once those values are entered, the FueLab calculator will populate the estimated fuel pump flow rate required to meet your needs.

Out With The Old, In With The New

To begin the installation we removed the factory fuel tank to make way for the lighter aluminum fuel cell. The fuel cell gave us a perfectly flat surface to mount a larger fuel pump without the hassle of retrofitting something in the factory tank. Since modern fuel tanks are made from plastic, they can be challenging to modify safely.

For our combination, we used the calculator and decided that a FueLabs twin screw brushless fuel pump (PN 93903) would be a perfect fit as it can support 1,250-plus horsepower at 60 psi fuel pressure while consuming less than 10 amps of current, making it one of the most efficient single-pump offerings available anywhere.

Because we are in Texas and this truck will be used for drag-and-drive events, we liked using an in-tank pump over an external unit. This pump will stay cooler since it’s submerged in fuel, and we need all the help we can get in the Texas heat.

The first step was to find a location that wouldn’t interfere with the fuel level sensor or the fuel fill opening. We used the mounting flange as a template to mark a cutting point on the top of the fuel cell. We then used the appropriate-sized hole saw to match the opening in our mounting ring. Use a file or some sandpaper to clean up the rough edges.

After deburring the hole, we installed the pump assembly to ensure it fit freely without binding against the opening. Now is the time to check the small things to avoid significant problems later. If the pump binds, use a file to enlarge the opening gradually. With the pump in its new home, we drilled 12 holes to secure the mounting ring to the cell. We used a center punch through the mounting ring to ensure the accuracy of the holes before drilling.

After the holes are drilled, debur them and clean out any shavings that might be left inside the fuel cell. We used a shop vacuum to suck out debris in the cell. We then used a microfiber towel to wipe it down to ensure that any trash we might have missed was removed. Metal shavings and garbage in a fuel system will kill the components. So, take your time and make sure everything is clean before proceeding with the installation. With everything tidy, we placed the gasket and secured the mounting ring with the supplied hardware.

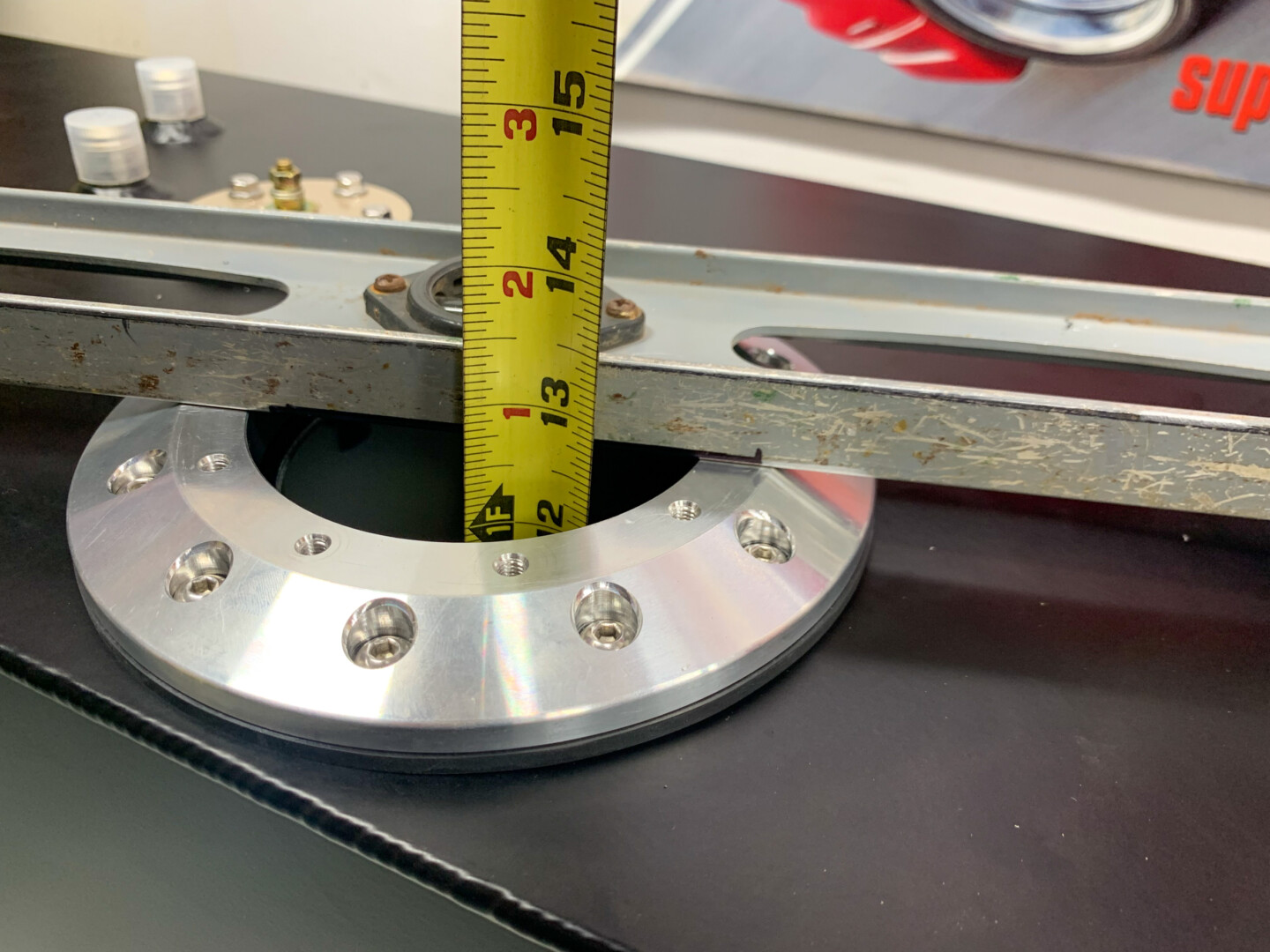

Since the fuel pickup tube is height adjustable from a minimum of 8 ¾- to a maximum of 15 ½-inches, we needed to measure the depth from the top of the flange to the bottom of the cell. The best method for this was to use a straightedge and a tape measure to get an accurate measurement.

Eliminating Starvation

You must run a straining filter at the pump’s inlet, so we used a Holley Hydramat as a pre-filter. The Holley Hydramat is a fuel reservoir system designed to address one of the most common challenges in high-performance vehicles: fuel starvation. During aggressive driving and acceleration, the fuel in the tank can slosh around, causing air to be introduced into the fuel lines, leading to engine misfires, power loss, and potential damage to the engine. The Hydramat takes care of all these issues, so we never need to worry about fuel starvation under heavy acceleration. You will need to consider the thickness of the pre-filter (Hydramat, in our case) when adjusting the length of the pickup tube.

After some careful measuring, we cut the pickup tube with a cutter before flaring it to accept the -8 AN adapter fitting. We then attached it all to together using the supplied compression fitting for the fuel pump. Finally, it was time to lower it into the fuel cell and see if we got our measurements correct. Fortunately, we did.

Below is an inside view of the fuel cell; notice the Holley Hydramat is touching the bottom. This placement ensures that fuel is picked up evenly and the pump won’t be starved of fuel. If it was pressed into the cell floor, it could cause a restriction.

Filtered Flow

With the fuel pump in place, we will focus on the FueLabs fuel filter (PN 81832-1). The FueLab filter is an -8 AN inlet/outlet filter with a compact design and a short 3-inch length. It features a 6-micron micro-fiberglass element, making it compatible with gasoline, diesel, methanol, and ethanol fuels. It is durable, sleek, constructed with billet aluminum, and anodized per military MIL-A-8625 Type II standards. The filter supports a flow rate of 200 gallons per hour (gph) and comes with -8 AN male inlets and outlets. It includes a low-profile saddle clamp mounting bracket for easy installation. Additionally, the filter element is replaceable, and the unit has a maximum pressure rating of 200 psig.

The last step in this fuel system upgrade is to install an electronic fuel pressure regulator on the return side of the fuel rail (part #52902-1). It features a -8 AN inlet/outlet and a pressure gauge.

The 529 series electronic fuel pressure regulator is designed to work seamlessly with FueLab’s Prodigy fuel pumps. This regulator employs a patented method for demand-based flow control, capable of detecting changes in fuel demand before any shift in rail pressure occurs (U.S. Patent 7,810,470). The unit features an analog output that reads fuel flow on the return side of the regulator. Through the analog output, the regulator sends a signal to the fuel pump and either increases or decreases fuel pressure based on the demands of the engine.

This product offers the rapid response of a mechanically regulated system combined with the advantages of electronic flow control. It operates independently without additional connections, control boxes, or calibration. It is compatible with various fuels, including gasoline, diesel, methanol, and ethanol.

With our fuel system complete, it’s time to install everything in our Silverado. We still need to figure out the fittings and hose sizes needed to get fuel from the cell up to the engine, but we will do that after everything is in place and mounted on the truck. More on that subject next time.